Indexa-V: Custom Carbide Tooling Systems

Indexa-V custom carbide drill systems are designed to optimize performance and cycle time for the best sustainable productivity in specific production environments. By factoring physical attributes with application variables Indexa-V delivers a custom carbide drill system that will balance machine characteristics with production requirements to find a solution that cannot be achieved from off-the-shelf products.

The start-to-finish process of designing and producing a custom carbide drill system considers all particulars that apply to achieving the precise configuration, including:

- Type of machine tool

- Type of cutting media

- Feeds & speeds - cycle time

Physical characteristics

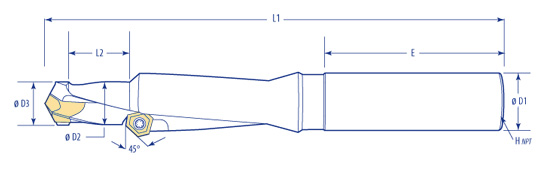

- Hole diameter (D1)

- Depth of cut (L4max)

- Total length (L1)

- Shank size (LS)

- Tolerances

- Chip removal - coolant

Secondary operations

- Counter-boring

- Chamfering

- Forming

- Step drilling